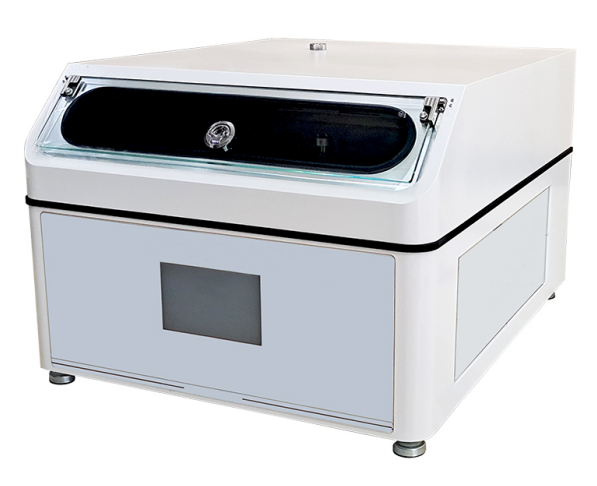

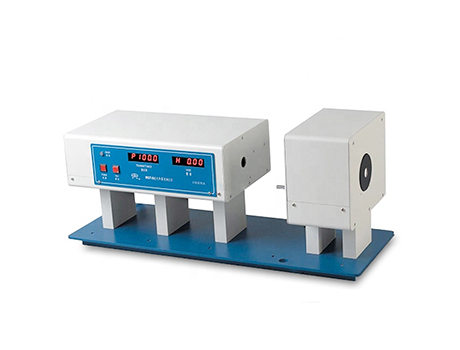

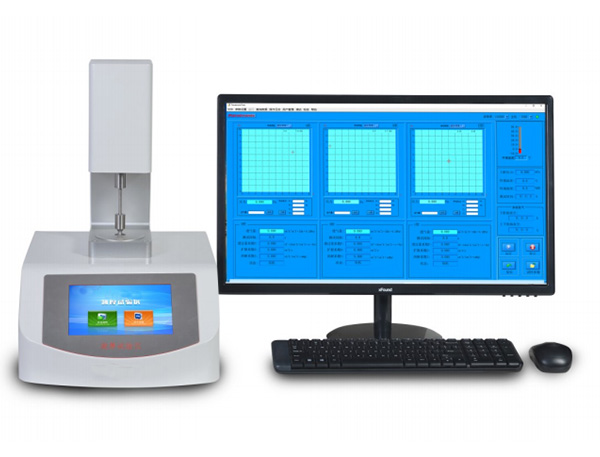

2.Can achieve the superposition of multiple data curve and display coordinates in various curve forms.

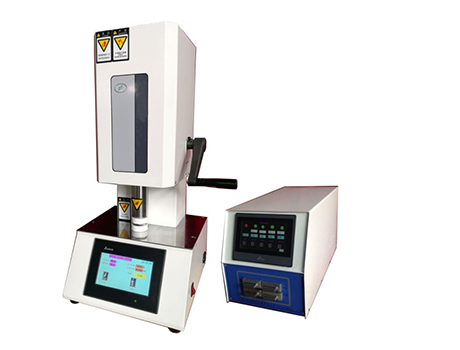

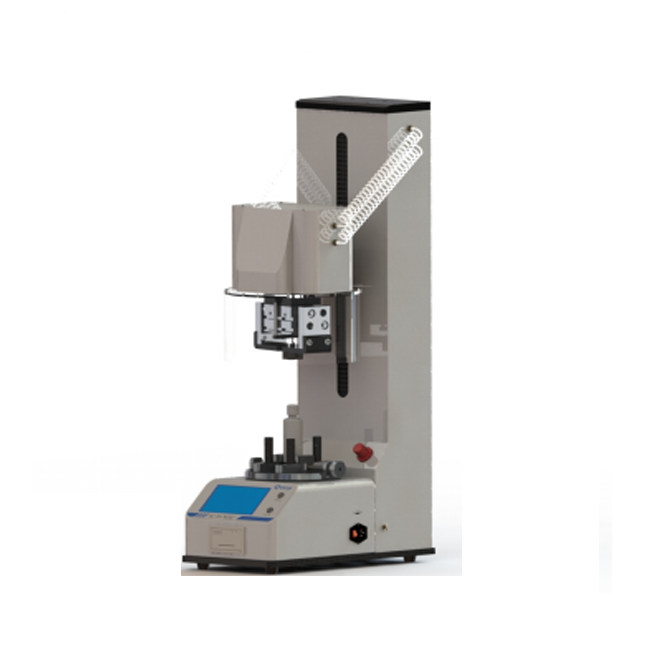

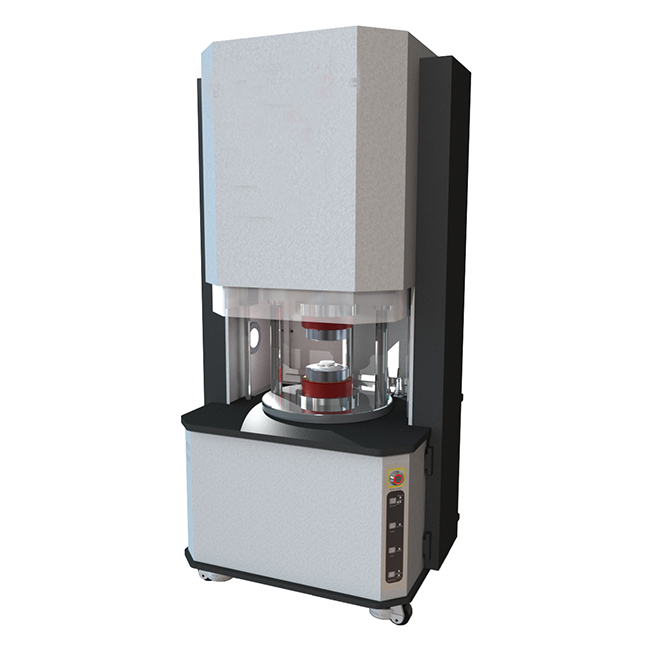

3.The load loading device of the instrument is designed reasonably, using high-precision pressure sensors for data acquisition, eliminating the traditional load sensor acquisition;Dual closed loop of software and hardware, achieving stepless adjustment of speed and loading force;Manual and automatic loading control can be used, which is convenient, fast, and accurate. Inductive manual displacement adjustment.

4.Regarding the coordinate axes of shear viscosity and shear rate curves: During the test, the coordinate axis is the normal coordinate axis. When the test is over, if you want to view the log coordinate axis image, you can directly adjust it with the mouse. So that you can observe the image in two ways, and the lowest point of the coordinate axis is set with the mouse after the test.

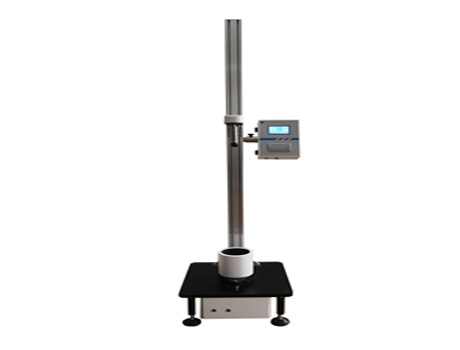

5.Scale display function, the displacement position of the material rod can be intuitively viewed.

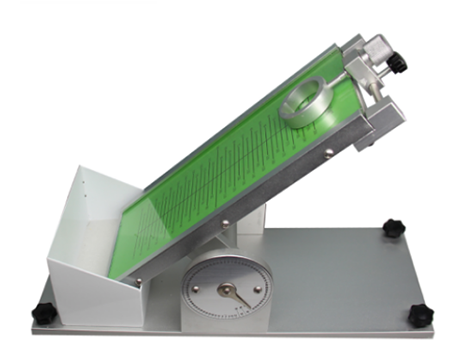

6.The whole machine structure adopts a "mouth"-shaped frame streamlined design to ensure structural strength, more beautiful appearance, stronger stability, and easier transportation and installation.

7.Scalability:This instrument can be expanded to double pressure head test mode without replacing the host.

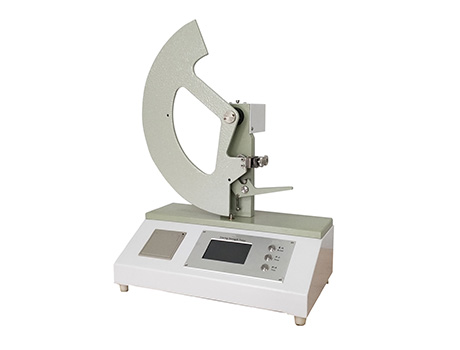

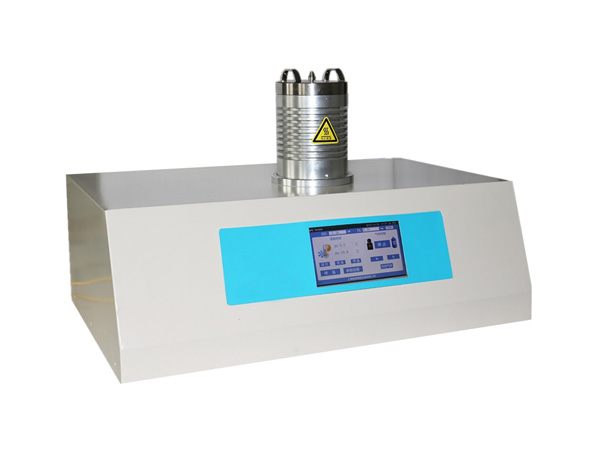

8.Electric auxiliary cleaning.

9.The furnace body can be rotated 90 degrees to facilitate auxiliary cleaning.

10.Adopts the upper body movement loading and pressurization mode with overall movement and dual kinetic energy; the pressurization is more stable;

11.Wireless remote control device loading

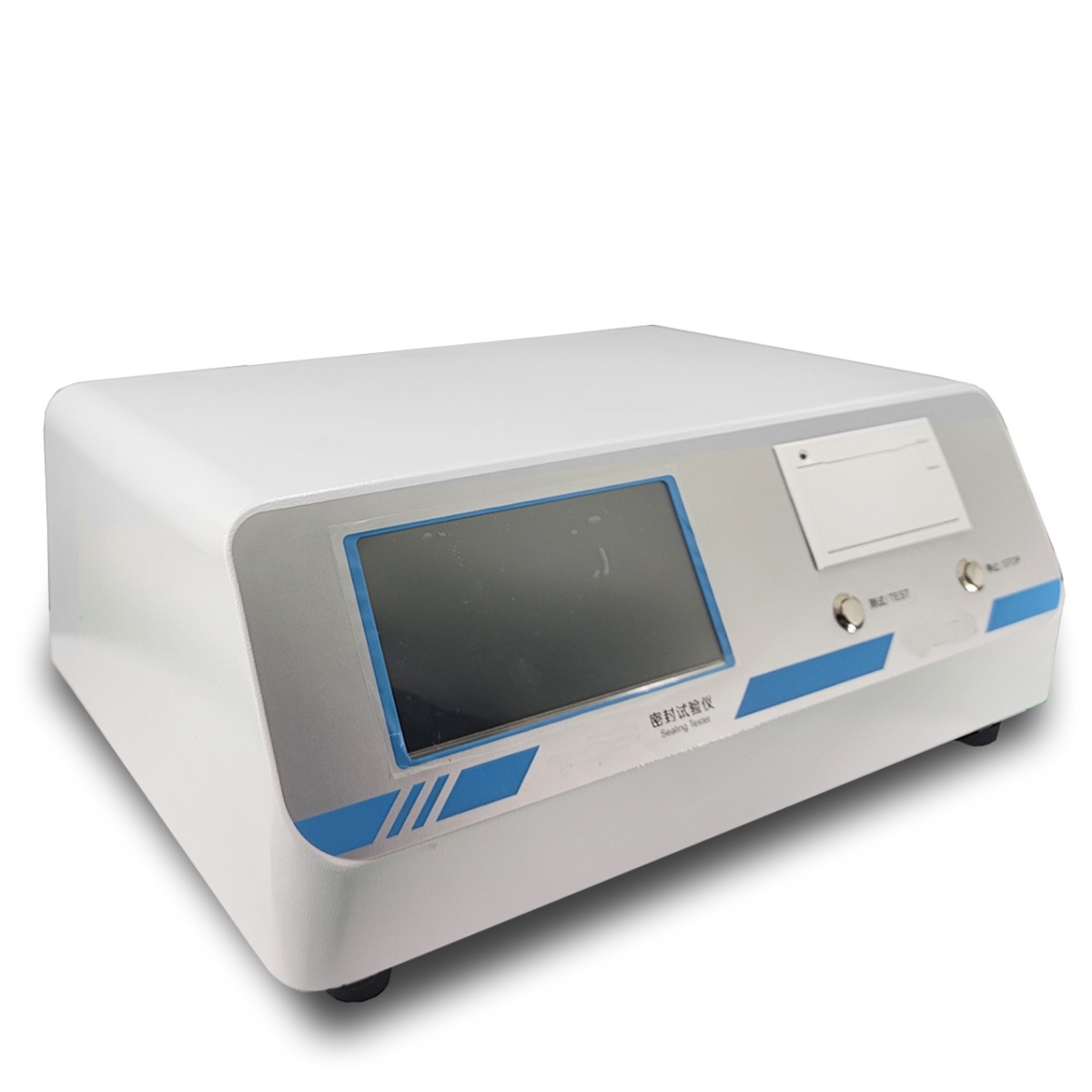

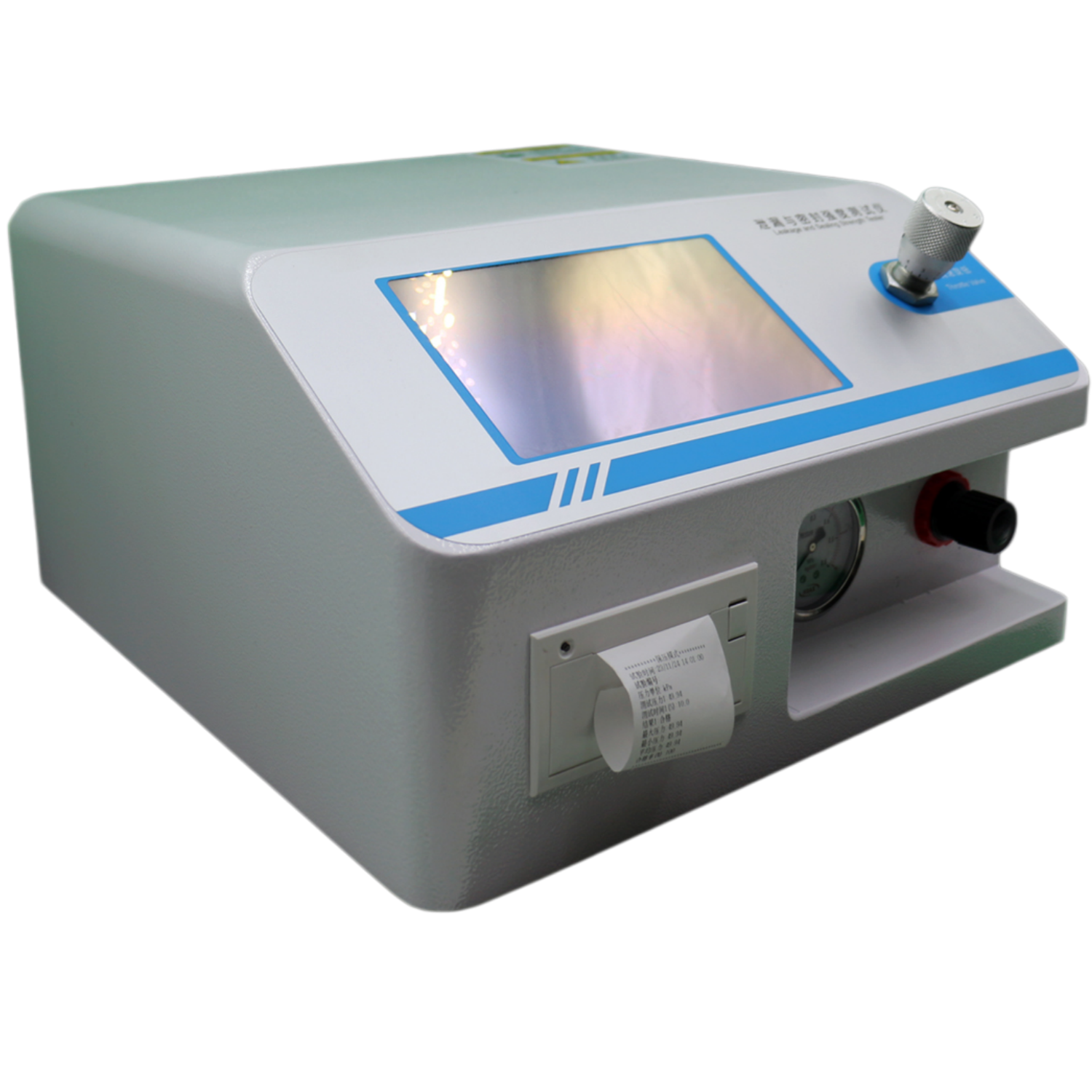

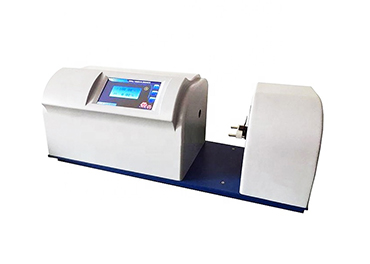

12.Streamlined design, strong sense of technology

13.The simple and clear decoration makes the overall feeling fresh and eye-catching.

14.Tungsten carbide die, high hardness, high temperature resistance, corrosion resistance, wear resistance.