Product center

Your Location:Home > PRODUCTS>Plastic and Rubber Testing Equipments

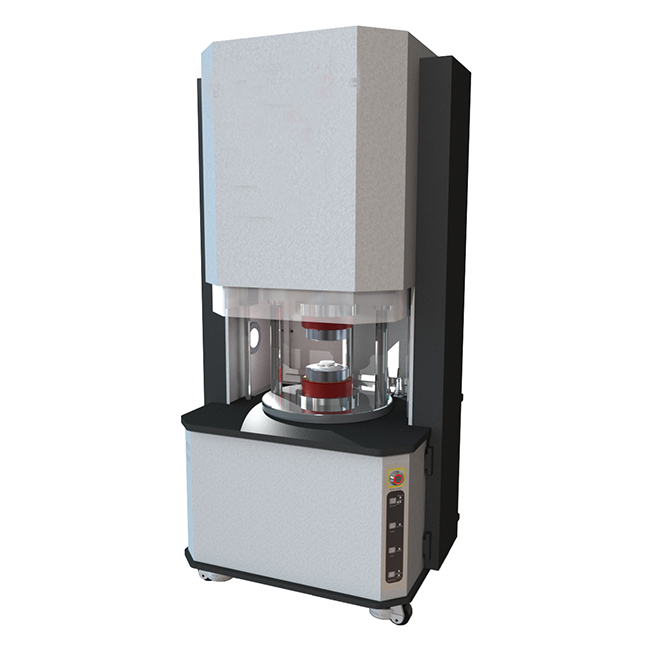

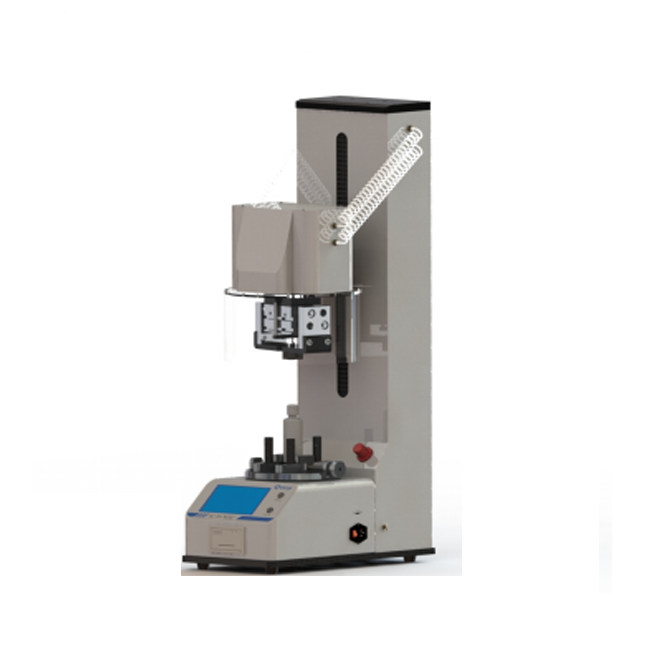

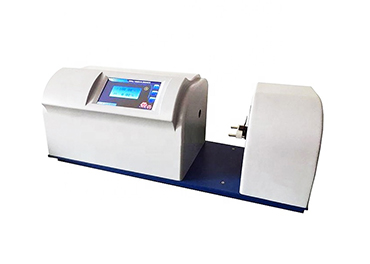

XHS-WVTR Water Vapor Transmission Rate Test System

Product Category:Plastic and Rubber Testing Equipments

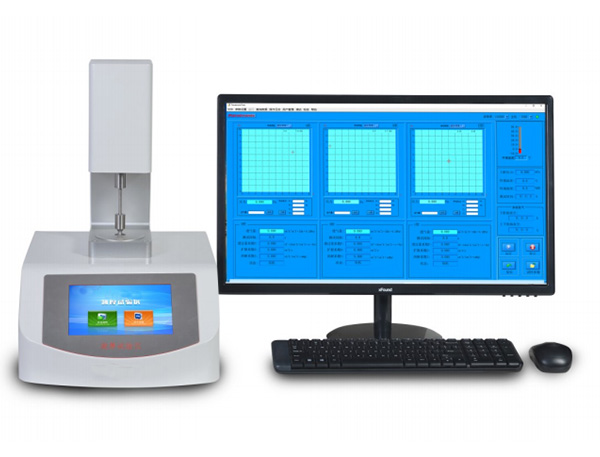

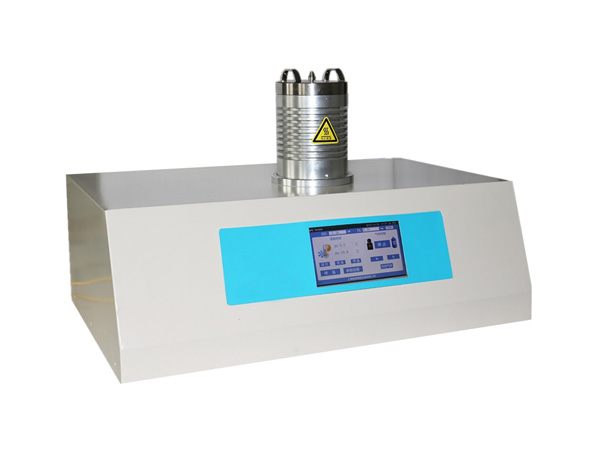

XHS-WVTR Water Vapor Transmission Rate Test System, is designed and manufactured based on infrared sensor method and conforms to the requirements of ISO 15106-2 and ASTM F1249. This instrument can be used to measure the water vapor transmission rate of barrier materials with high, and medium moisture barrier properties with a wide testing range and high testing efficiency. The instrument is featured with patented design of integrated block consisting of 3 test cells. Equipped with high precision sensors and professional computer-controlled system, the instrument can regulate and control the temperature, humidity and flow rate precisely, which guarantee the testing sensitivity and repeatability of test results. XHS-WVTR is applicable to determination of water vapor permeability of plastic films, sheeting, paper, packages and other relative packaging materials in food, pharmaceutical, medical apparatus, consumer goods, photovoltaic and electronic industries, etc.

Principle:

The test specimen is mounted in the diffusion cell, which is divided into a dry chamber and a controlled-humidity chamber. The dry side of the specimen is swept by a flow of dry nitrogen, and the water vapor permeating through the specimen from the controlled-humidity chamber is carried by dry nitrogen to the infrared sensor where proportional electrical signals will be generated. The water vapor transmission rate is obtained by analyzing and calculating the electrical signals. For whole package specimens, the dry nitrogen flows inside the specimen while the outside of specimen is maintained in a high humidity environment.

ISO 15106-2, ASTM F1249, GB/T 26253, JIS K7129, YBB 00092003-2015

Embedded high-speed microcomputer chip , simple and efficient human-computer interface, providing users with a comfortable and smooth operating experience |

Automatic flow control: The test flow, including carrier gas and moisture, automatically controlled without manual intervention |

Fully automatic temperature control, water bath cooling and heating temperature control technology, the equipment can change the temperature of the whole machine under the environment change of 5~40 degrees Celsius, and can be heated and cooled arbitrarily, with high control accuracy, stability and reliability, and the equipment is not disturbed by the external ambient temperature |

Automatic humidity control: automatic humidity control, no mechanical knob, no manual intervention |

Touch Screen Operation (Optional Purchase) |

Professional test software support, real time display test data and graphs. |

Imported high-speed and high-precision acquisition chips can effectively ensure test accuracy and real-time performance |

One-key operation, simple and convenient. |

Fully automatic test: set test parameters, the test will be carried out automatically after the start, automatically judge the end of the test and save the test results. |

Infrared sensor with laser pulse modulation, long optical path absorption, higher measurement accuracy |

Precision pipelines and valves, patented pipeline flushing technology, ensure the cleanliness of the carrier gas, and the test efficiency is higher |

The installation technology of anti-side leakage sealing of the sample enhances the sealing of the sample. |

High-efficiency test, low nitrogen consumption |

Meet the requirements of GMP for data traceability, authority management and other functions, and the computerized system fully meets the needs of the pharmaceutical industry (optional Purchase) |

Test Range | Film:0.005-40g/(m2·24h) |

Resolution | 0.001 g/(m2·day) |

Standard Test Area | 50cm2 |

Specimen Thickness | ≤3mm |

Test Chamber | 3 Test Chambers |

Temperature Control Range | 10C-55C |

Temperature Control Accuracy | ±0.2C |

Test Humidity | 0-100%RH |

Humidity Control Accuracy | ±1% |

Carrier Gas | 99.999% High-purity Nitrogen (outside of supply scope) |

Flow of Carrier Gas | 0-200 mL/min |

Carrier Gas Pressure | ≥0.28MPa/40.6psi |

Port Size | 1/8 inch metal tubing |

Calibration Method | Standard Test Film |

Dimension | 350mm (L)×695 mm (W)×410mm (H) |

Power Supply | AC 220V 50/60Hz |

Weight | 60Kg |

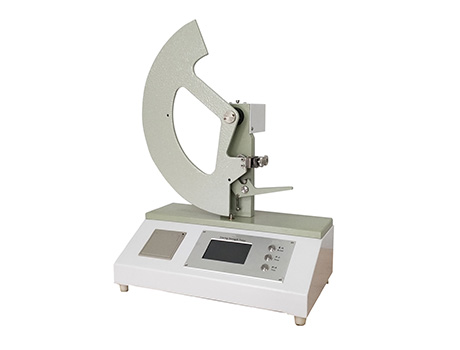

XHV-01C Elmendorf Tearing Strength Tester

XHS-11 Lasting Adhesion Tester

XHS-37A Mooney Viscometer

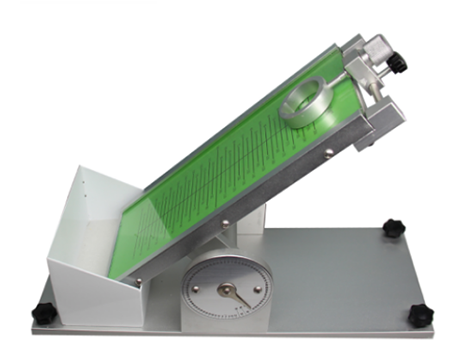

XHS-65 Guillotine Stiffness Tester

XHS-02A Pneumatic Sample Press

XHS-07 Oxygen Index Tester

XHS-05Q Carbon Black Content Tester

XHS-OTR Oxygen Transmission Rate Test System

XHS-39D Lab Twin Screw Extruder

XHS-60 Gelbo Flex Durability Tester

XHS-10 Primary Adhesive Tester

XHS-18 Salt Spray Chamber

XHS-37B Rubber Testing Rheometer With Rotorless Curemeter

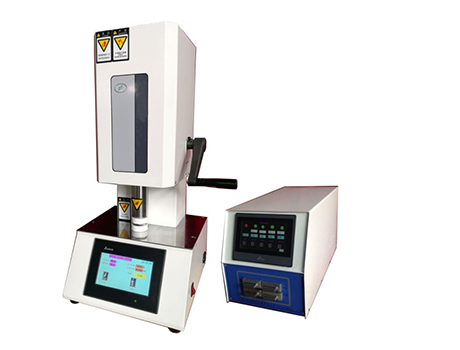

XHS-03 Melt Flow Indexer

XHS-08 Coefficient of Friction Tester

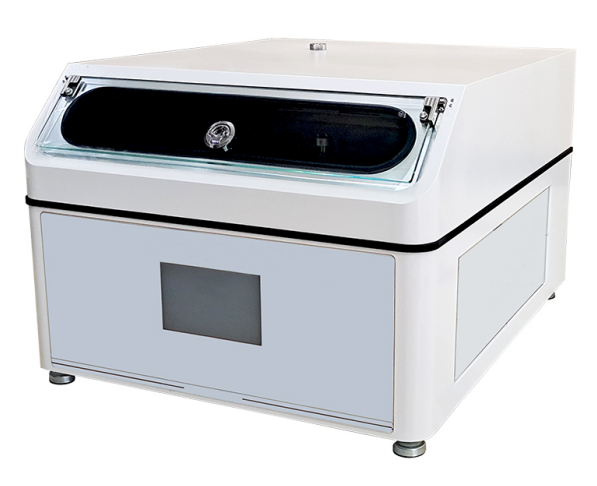

XHS-WVTR-C6 Water Vapor Permeability Rate Tester

XHS-14 Heat Seal Tester

XHS-15B Vicat Softening Temperature and HDT Machine

XHS-43A Film Free Shrink Tester

XHS-55 Capillary Rheometer

XHS-56 Wallace Rapid Plastimeter

XHS-20 Plastic Bars Bending Tester

XHS-36 Low Temperature Brittleness Tester

XHS-ML-D Computer Controlled Capillary Rheometer Product introduction

XHS-12 Laboratory Dry Oven

XHS-50 Polarized Stress Tester

XHS-21 Friction and Peel Tester

XHS-39CT Filterability Tester

XHS-39A Lab Injection Molding Machine

XHS-03AT Melt Flow Indexer

XHS-49 Benchtop Thickness Tester

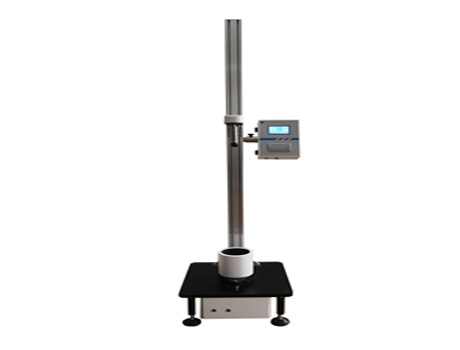

XHS-09 Falling Weight Impact Tester

XHS-GT-V1/V3 Gas Permeability Tester

XHS-05T Thermal Gravimetric Analyzer

XHS-16D Automatic Bottle Cap Torque Tester

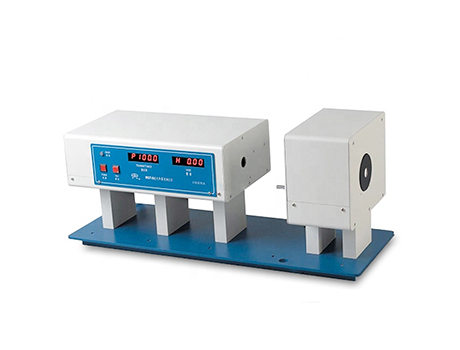

XHS-04B Haze Meter

XHS-15A Vicat Softening Temperature and HDT Machine

XHS-04A Haze Meter

XHS-17 Falling Dart Impact Tester

XHS-19 SPI Vinyl Plastic Film Flammability Tester

XHV-01B Elmendorf Tearing Strength Tester

XHS-38 Accelerated Aging Oven

XHS-35 Ross Flexing Tester

XHS-05S Carbon Black Dispersion Tester

XHS-04C Haze Meter

XHS-13 Fogging Tester

XHS-42 Automatic Densimeter

XHS-01 Charpy and Izod Impact Testing Machine

XHS-43C Thermal Shrinkage Tester

XHS-16 Bottle Cap Torque Tester

XHS-45 Pipe Hydrostatic Pressure Testing Machine

XHS-05 Differential Scanning Calorimeter

XHS-05ST Thermal Conductivity Tester

XHS-06 Digital Vacuum Leak Tester

XHS-40 Smoke Desity Tester

XHS-03CT Capillary Rheometer

XHS-47 Methylene Chloride Tester

XHS-02D Automatic Sample Notcher