Product center

Your Location:Home > PRODUCTS>Paper and Packaging Testing Equipment>Pulp Tester

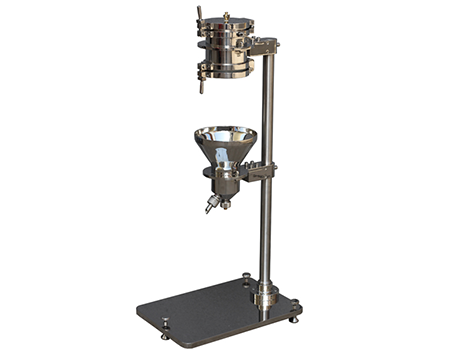

XHV-15A Schobel Pulp Meter (SR) is designed for precise measurement of pulp suspension beating degree (SR value) and evaluates fiber filtration performance through standardized dewatering processes. It is suitable for quality control in the paper industry, R&D laboratories, and third-party testing institutions, meeting international standard testing requirements.

Application Area

· Paper production line: real-time monitoring of pulp beating degree and optimization of pulp grinding process.

· Laboratory research: evaluate the water filtration characteristics of different fiber raw materials to guide formula improvement.

· Quality inspection and certification: pulp product compliance test and export standard verification.

DIN EN ISO 5267-1, SCAN C19M3, and BS 6035-1

· Accurate SR value measurement: The digital version uses a high-precision sensor with 0.1 SR resolution, supporting real-time display and data export.

· Multi-mode operation: Manual, pneumatic, and digital versions are available, suitable for different experimental scenarios.

· Temperature compensation technology (digital version): automatically correct the influence of ambient temperature on the measurement results.

· Safety design: One-click start (compliant with safety specifications), sealed cone to prevent leakage, ensuring safe operation.

Optional Models

XHV-15AA (Manual) | The basic model features a graduated cylinder for direct SR value measurement, eliminating the need for external power. |

XHV-15AB (Pneumatic) | The compressed air drives the cone to lift, improving the operation efficiency, suitable for medium and high frequency testing. |

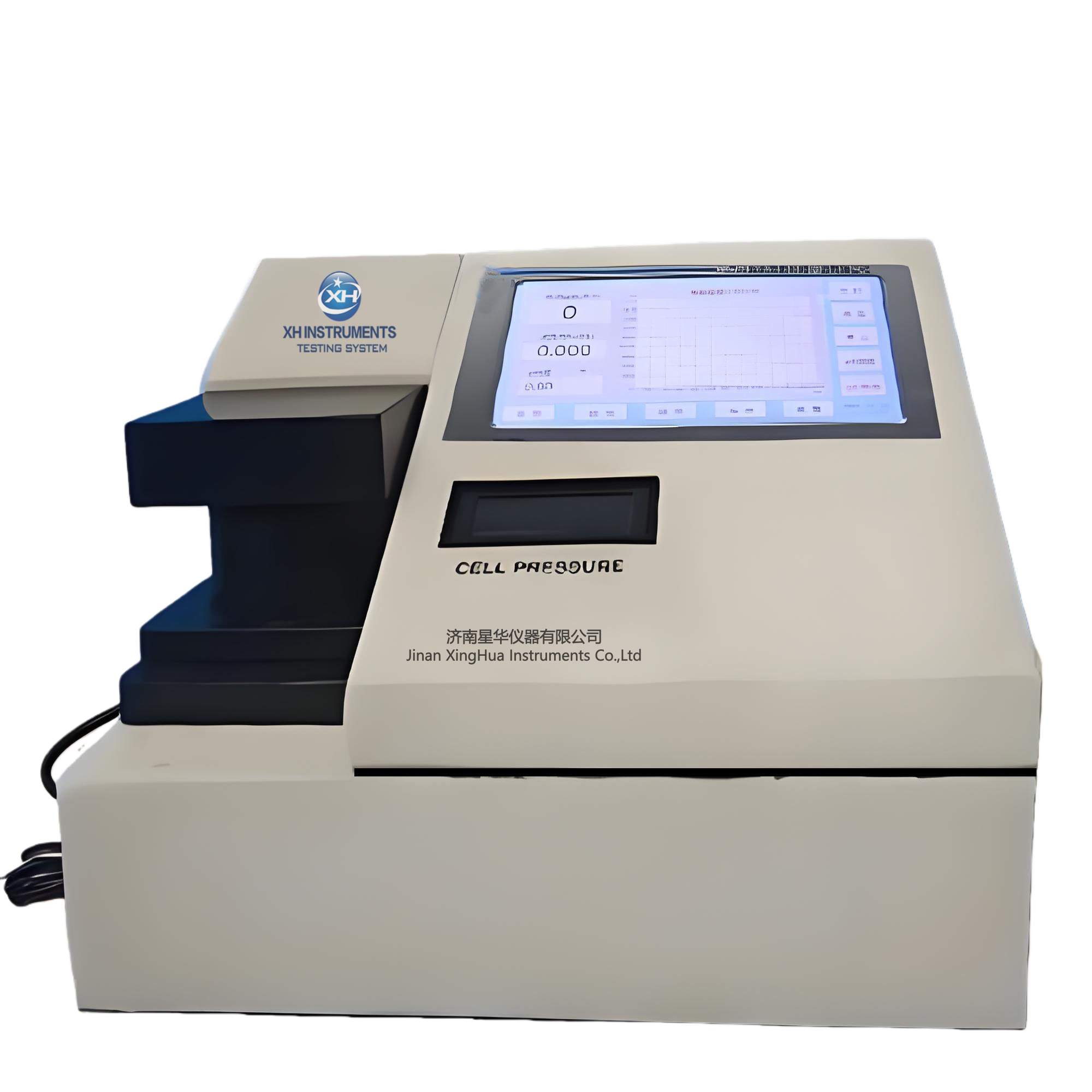

XHV-15AC (Digital) | Integrate digital display, temperature compensation, and data printing functions. |

Technical Parameter

Class | Define |

Measuring Principle | The pulp suspension is dehydrated through ISO standard screens. The filtrate is diverted via a separation funnel, with overflow collected through side pipes. |

Measuring Aange | Pulp strength (SR value): 0-100 SRU (displayed directly in digital version with temperature-compensated SR value; for manual/pneumatic versions, read via measuring cup). |

Accuracy | Digital version: ±0.1 SR; manual/pneumatic version: ±1 SR. |

Key Structural Parameters | Overflow discharge time: 149±1s Remaining volume: 7.5-8.0 mL Pyramid rise speed: 100±10mm/s Screen mesh size: ISO standard compliant (calibration screens replaceable) Separation funnel capacity: Dual outlet design, compatible with SR measuring cup. |

Power Supply | Pneumatic version: 4-6bar compressed air (6mm interface); Digital version: 100-240V wide voltage, 50/60Hz, power consumption <25W. |

Operational Environment | Temperature: 10-40°C, humidity ≤80% RH (non-condensing). |

Device Material | Shell and dehydration assembly: 304 stainless steel; screen and sealing cone: wear and corrosion resistant special alloy. |

Size And Weight | 350×380×870 mm (length×width×height); Net weight: 32kg; gross weight including packaging: 60kg. |

XHV-ZPA Zeta Potential Analyzer

XHV-40 Particle Charge Analyzer

XHV-17 Valley Type Beater

XHV-18A Vertical Standard Pulp Disintegrator

XHV-29 Rapid Koethen Sheet Former

XHV-27B Water Circulation Handsheet Former

XHV-DFR Dynamic Retention Analyzer

XHV-15B Canadian Standard Freeness Tester

XHV-45 Bauer-McNett Fractionator

XHV-18C Standard Vertical Pulp Disintegrator

XHV-28 Tappi Manual Sheet Forming Machine

XH-WRVT Water Retention Value Tester

XHV-15ST Canadian Freeness Tester

XHV-18D Fiber Disintegration and Dispersion Apparatus

XHV-27A Water Circulation Handsheet Former

XHV-36 Somerville Shive Content Analyzer

XHV-19 Laboratory Rotary Digester

XHV-16 PFI Pulp Beater