Product center

Your Location:Home > PRODUCTS>Fabric and Yarn Testing Equipments>Flammability Tester

XHF-19S Radiant Flooring Panel Apparatus

Product Category:Flammability Tester

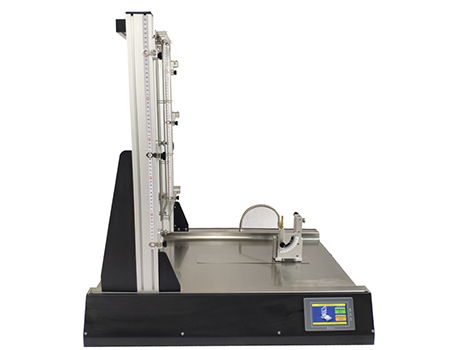

Critical Radiant Flux is the main parameters of the fire risk for flooring materials, It reflects the burning and spreading ability of flooring material specimen under external heat radiation conditions, It is an important index of combustion classification for building products. According to related test standards requirements, and XHF-19S Radiant Flooring Panel Apparatus is measuring the critical radiant of combustion floor coverings, through the radiation environment of test chamber. It is can also be used to measure the critical radiation of the cellulose insulation floor material.

• ISO 9239-1: Flooring fire reaction test - Part 1: Combustion performance of flooring materials tested by radiant heat

• ISO 9239-2: Flooring fire reaction test - Part 2: Testing flame spread status under the heat flux is 25kW/m2

• ASTM E 648: Critical Radiant Flux of Floor standard test - covering system uses radiant heat energy

• ASTM E 970: Using a Radiant Heat Energy Source, test insulation floor insulation standard test for Critical Radiant Flux Using a Radiant Heat Energy

•NFPA 253: Standard Test Method for using radiant heat energy, test plates overlay system Critical Radiant Flux

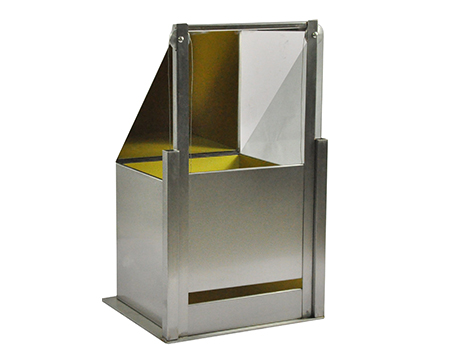

1. All structural components are made of stainless steel, appearance,and corrosion resistance

2. The radiation source is a porous ceramic heat radiating plate of 300mmX450mm, and tilted 30 degree

3. The calorimeter is imported from Europe , range 50kW/m2

4. The igniters diameter is 0.7mm, 19/EA, is located at the bottom of the center line of each 60°

5. The standard plate is made of calcium silicate without coating layer,which is size of 1050X250mm and thickness is 20+/-1mm ,density is 850 +/- 100kg/m³

6. Small stainless steel auxiliary ignition burner ignited sample.

7. Inlet flow control valve, precise control of propane flow

8. Equipped with air blower providing air, mixed gas through the venturi mixing gas

Optical System:

1. The optical system comprising a light source color temperature is 2900 +/- 100 K incandescent, light receiving silicon photodiode with an optical path test shutter, 0% and 100%, to facilitate the use of calibration

2. Imported light battery module measuring light attenuation. The system automatically calculates and generates a light transmittance curve translucent; printable Scribble

Thermal radiation system:

1, Heat radiation pyrometer accuracy of +/- 0.5C, away from the radiation board about 1.4m

2. Radiation pyrometer sensitivity constant in the wavelength range 1um - 9um

3. High-performance K-type thermocouples diameter 3.2mm, having insulation and ungrounded hot junction; in the lower box roof 25mm, the inner wall of the rear housing flue 100mm

4. Should be used to detect a diameter in the range of 250mm, blackbody radiation temperature within a temperature range of 480 C- 530 C count regulate the heat radiation panel surface heat flux 5, Within the error range, measured from the heat radiating plate to the heat flux within 110mm - 910mm wide, 110mm intervals.

XHF-19E Horizontal Flammability Tester

XHF-19F Carpet Flammability Tester

XHF-19B Fabric 45 Degree Flammability Tester

XHF-43 Surface Flash Tester

XHF-19T Toy Flammability Tester

XHF-19G Blanket Flammability Tester

XHF-19A Vertical Fabric Flammability Chamber

XHF-19C Vertical Fabric Flammability Tester

XHF-19D Sleeping Bags Flammability Tester