Product center

Your Location:Home > PRODUCTS>Pharmaceutical Testing Equipments

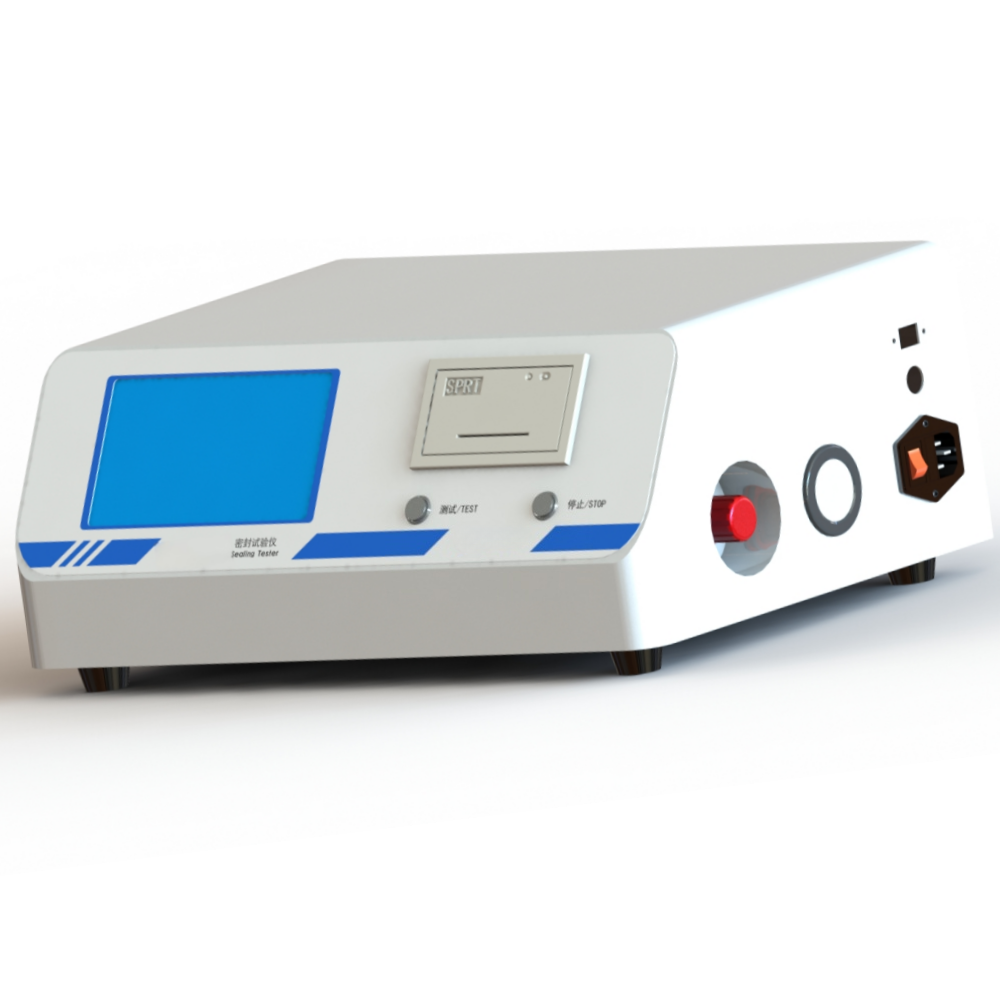

XHD-03 Packaging Leak Tester

Product Category:Pharmaceutical Testing Equipments

Packaging leak tester is suitable for sealing integrity testing of pharmaceutical packaging to prevent moisture, oxygen, and microorganisms from contaminating products. Medicines: bottled, bagged, boxed, ampoules, vials, cartridges, prefilled needles (PFS), (BFS), (FFS), etc.

Spray cans: plunger spray cans; bag-lined spray cans; "energy jacket" spray cans; flexible tube spray cans.

USP <1207>, ASTM F2338 standards and FDA standards

◎Comply with USP <1207>, ASTM F2338 standards and FDA standards.

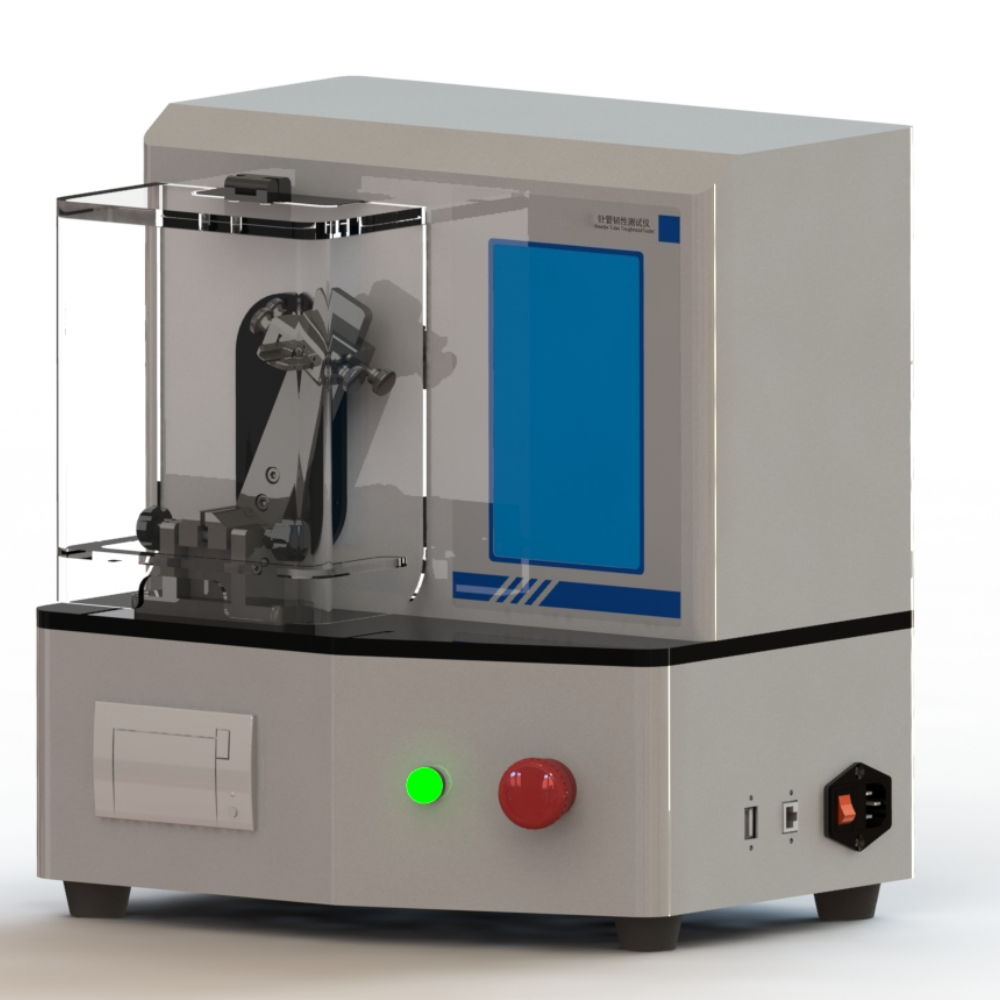

◎Semi-automatic detection, suitable for small batch and multi-variety testing.

◎Non-destructive non-destructive testing, high accuracy, repeatability, sensitivity.

◎The instrument is used for vacuum pressure difference detection.

◎The leak rate can be automatically converted into defect aperture μm.

◎Database storage of test results for easy quality management.

◎Database storage of test results for easy quality management.

◎Touch-type man-machine interface, simple and quick operation: after setting/selecting the test program, only need to manually put in/take out the test sample.

Advantage function:

◎Automatically test the flow rate and change the aperture size during the whole process.

◎Automatic leak rate calibration function.

◎Equipped with standard leaks (standard positive bottles, with third-party certification).

◎Four-level user authority management meets FDA 21CFR PART 11 requirements.

◎With audit trail function.

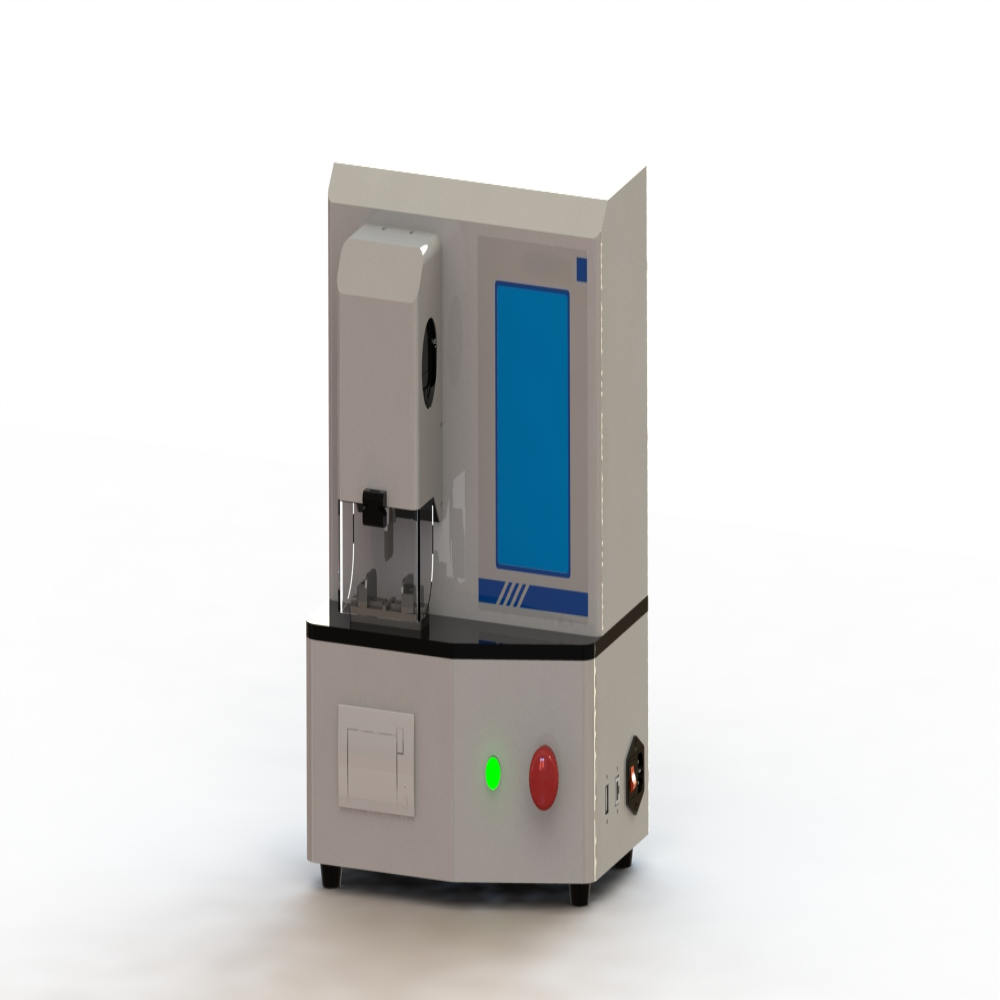

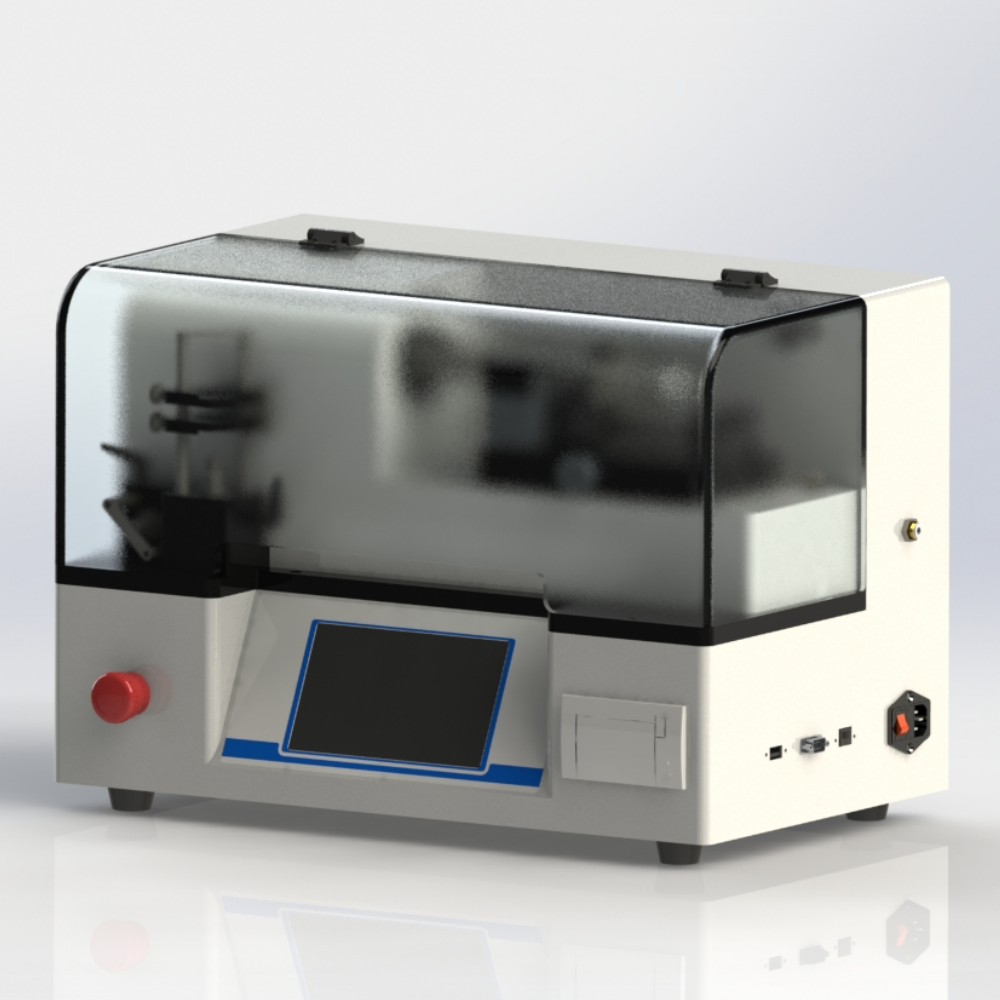

◎Split design, the test chamber is located above the host, and various test chambers can be provided according to different product types.

◎We also provide users with supporting services related to tightness testing, including positive bottle production, standard leak rate/annual leak verification, new sample mold customization, sample methodological parameter development and verification, etc.

◎The test cavity is customized according to customer needs to ensure that the test cavity is fully matched with the customer's product, and rapid and sensitive testing.

Differential pressure sensor | ±2kpa, error≤0.5%F.S. |

Differential pressure resolution | 0.1pa |

Test pressure sensor | Error≤±1%F.S. |

Test pressure range | -0.1~0.2MPa/-0.1~0.7MPa/-0.1~1.0MPa |

Minimum detectable aperture | 2μm

|

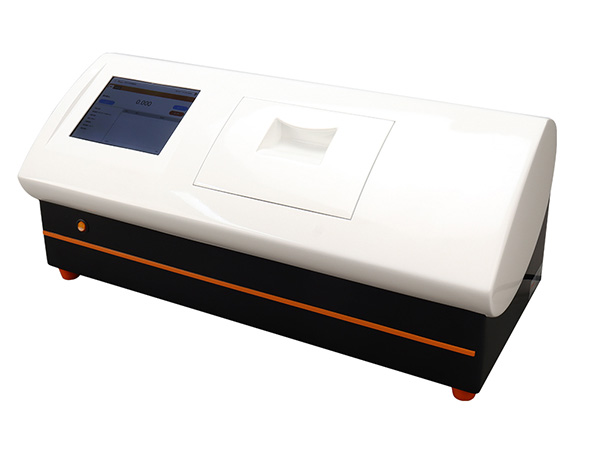

Display method | 10-inch touch color touch screen |

Voltage | AC100V-240V, 50/60Hz, power ≤200W |

Weight | Host: about 30kg |

Audit trail | ≥5 years of storage Multiple event logs, which can be queried according to time |

Authority management | Login with username and password, level 4 authority, meet FDA 21CFR PART 11 requirements |

Print function | External micro printer |

History record | ≥5 years storage |

Data backup | Support U disk to export data |

Signal output | (4-20) mA, RS485, 12V alarm output |

Interface | Ethernet USB RS485 |

XHD-04A Glove integrity tester

XHD-05A Medical Needle Tubing Stiffness Tester

XHD-05 Freezing Point Osmometer

XHD-08 6% Luer Taper Comprehensive Performance Tester

XHD-11 Syringe Sealing Positive Pressure Tester

XHD-09 Positive and Negative Pressure Integrated Sealing Tester

XHD-07 Medical Needle Toughness Tester

XHD-04 Medical Needle Penetration Force Tester

XHD-04B Glove integrity tester

XHD-01B Filter integrity tester

XHD-IU UV-VIS Spectrophotometer

XHD-PO Automatic Polarimeter

XHD-01A Filter integrity tester

XHD-06 Syringe Sealing Negative Pressure Tester

XHD-01C Filter integrity tester

XHD-04D Total Organic Carbon Analyzer

XHD-02A Total Organic Carbon Analyzer

XHD-02B Total organic carbon Analyzer

XHD-02C Total organic carbon Analyzer

XHD-ADR Auto Digital Refractometer

XHD-10 Catheter and Guidewire Friction Tester

XHD-MPA Melting Point Tester